From Japan to Turkmenistan with 200 excavators and bulldozers

M&M Militzer & Münch Turkmenistan is involved in a major national transport project between the State Committee for Water Management…

Cranes at sea

Militzer & Münch Turkmenistan Ltd. offers its customers comprehensive transport logistics services in the fields of road, air, sea, and…

Transports to fight hunger

Militzer & Münch supports the World Food Programme in the fight against famine and delivers food from Tajikistan to…

On board six trucks from China to Uzbekistan

Within only 20 days, Militzer & Münch’s Asia specialists transported power generation equipment, a total weight of almost one hundred…

Market study participation

St. Gallen, October 6, 2022. How do shippers cope with the fluctuating freight rates in logistics? The University of St.…

Multimodal via the Middle Corridor

The Middle Corridor is currently gaining ground as a promising alternative to the Northern Corridor of the New Silk Road.…

Rail as an alternative

Containers are currently in short supply worldwide, and there is a lack of capacity on ships – a problem, especially…

Too big for any door

Out-of-gauge: between May and October 2021, Militzer & Münch transported seven autoclaves to Uzbekistan for a manufacturer of construction and…

52 trucks – from door to door

More than 50 trucks with numerous components started on their route in Germany and Estonia in spring. Overland and by…

Metal roof tiles – from Poland to the USA

An entire roof on one pallet? No problem for a roof tile manufacturer in Poland. His products are also in…

Every Millimeter counts

Two days to send a complete packaging system from Schwäbisch Hall in South Germany to Dammam, Saudi Arabia – via…

75 Tons from Bursa to Ploieşti

Barely 900 kilometers separate the Turkish city of Bursa from the destination, the city of Ploieşti in Romania. Not too…

300 tons for the glass industry

Eleven trucks, ten of them oversized, on the road in two convoys, with special permits and escorts, three nights each,…

For space travel, a nighttime operation

Strictly confidential: in August 2020, Militzer & Münch transported a component for a launch vehicle. The customer was a company…

A factory at sea

Transporting an entire factory plant by sea from Belgium to India is an unusual project even for the experienced Militzer…

In the starting blocks, headed south and east

Despite the corona crisis, the Swiss Militzer & Münch unit was able to achieve a number of successes. Among other…

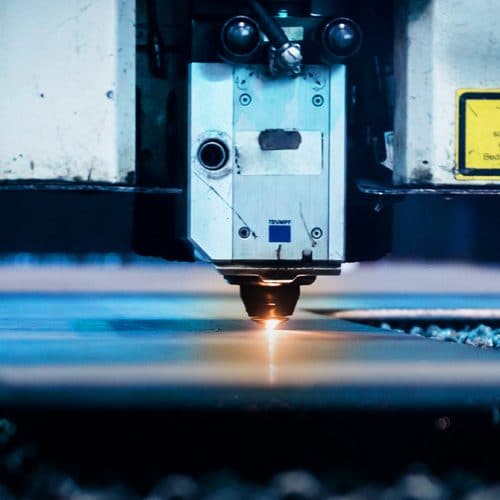

A Happy encounter

He was at the right place at the right time: at a trade fair, an importer of Chinese laser cutting…

Cell Phones in Flight Mode

Cell phones are regarded as dangerous goods – because of their batteries. This and more factors have to be taken…

For coffee lovers

Coffee is popular in Poland, and has become an export hit, too: After years of successful cooperation, one of the…

Freshly Polished

How do online retailers get the goods they sell? One of the largest international e-commerce corporations orders shoe polish, brushes…